SMC Composite Manhole Covers

Durability: Made from SMC (Sheet Molding Compound) composite material, these manhole covers are highly resistant to compression, impact, and corrosion, ensuring a long lifespan even in harsh environments.

Lightweight & Easy Installation: Compared to traditional cast iron covers, SMC composite manhole covers are significantly lighter, making them easier to transport, handle, and install, which reduces labor and installation costs.

High Safety: Designed with anti-slip surfaces, these covers enhance safety for both pedestrians and vehicles, preventing accidents caused by slipping or sliding, especially in wet conditions.

Environmental Friendly: The SMC composite material is recyclable, making it an eco-friendly choice that contributes to sustainable infrastructure development by reducing waste and environmental impact.

Theft-Proof Design: These covers can be equipped with locking mechanisms or anti-theft features to minimize the risk of theft, a common issue with metal covers, ensuring the manhole remains secure.

Product Details: SMC Composite Manhole Covers

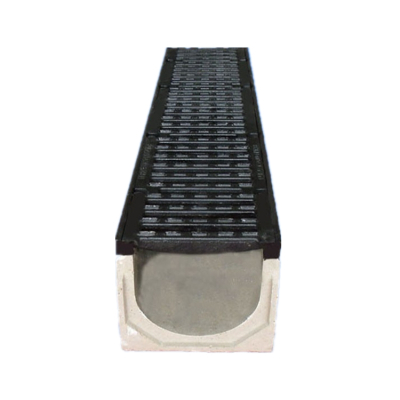

SMC Composite Manhole Covers are an advanced and highly durable solution for modern infrastructure projects, engineered to offer superior performance in challenging environments. Manufactured from Sheet Molding Compound (SMC) with glass fiber reinforcement, these manhole covers provide exceptional strength, corrosion resistance, and long-term reliability. With compliance to international standards such as EN124, these covers are suitable for a wide range of applications, from urban roads to industrial zones.

Key Features:

Superior Durability: Made from SMC composite material, these covers offer high resistance to corrosion, chemicals, and extreme weather conditions. They have a longer lifespan compared to traditional cast iron or concrete covers.

Lightweight & Easy Handling: Significantly lighter than metal covers, making transportation, installation, and maintenance more cost-effective and less labor-intensive.

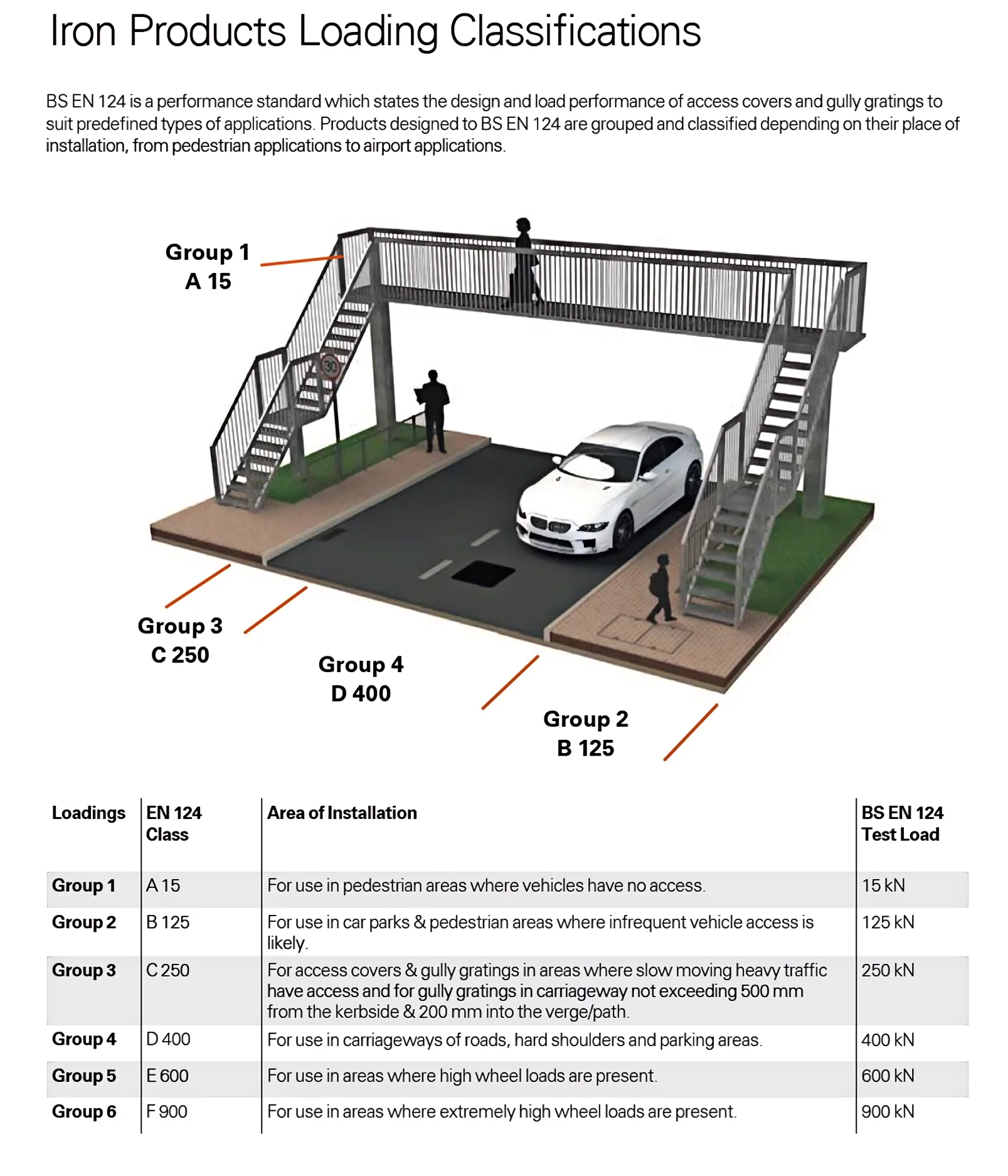

Load-Bearing Capacity: Tested to meet EN124 standards, these covers are available in different load-bearing classes, ranging from pedestrian areas to heavy-duty roadways.

Anti-Theft Design: Many models come with locking mechanisms or tamper-proof features, minimizing the risk of theft and ensuring that the covers remain securely in place.

High Safety Standards: The covers are designed with an anti-slip surface, providing enhanced traction for vehicles and pedestrians. This is especially beneficial in high-traffic areas or places prone to wet conditions.

Eco-Friendly: The SMC composite material is fully recyclable, making it an environmentally responsible choice for sustainable construction projects.

Aesthetic Design: Available in various shapes and finishes, these covers can be customized to fit the specific aesthetic and functional requirements of your project.

Applications:

Urban streets and roads

Sewage and drainage systems

Industrial and commercial zones

Residential complexes

Airports and ports

Parks and recreational areas

Technical Specifications:

| Parameter | Description |

|---|---|

| Material | SMC Composite (Sheet Molding Compound) with glass fiber reinforcement |

| Load Capacity | Complies with EN124 standard, available in different load classes: A15, B125, C250, D400, E600, and F900 |

| Size Range | Customized sizes available, standard sizes: 600mm, 800mm, 1000mm diameter, or square equivalents |

| Surface Finish | Anti-slip textured surface to enhance traction |

| Weight | 30-60% lighter than traditional cast iron covers |

| Temperature Range | -40°C to +80°C, suitable for extreme climates |

| Corrosion Resistance | Excellent resistance to salts, oils, and industrial chemicals |

| Anti-Theft Mechanism | Optional locking system or tamper-proof bolts |

| Recyclability | 100% recyclable, environmentally friendly |

| Standards Compliance | EN124 Load Classification, ISO 9001:2015 Certified |

| Customization Options | Available in different shapes, sizes, and colors for various applications |

Performance Benefits:

Impact Resistance: The SMC composite structure provides excellent shock resistance, reducing the risk of breakage or damage under heavy loads or accidental impacts.

Chemical Resistance: These covers withstand exposure to corrosive substances such as oils, salts, and various chemicals typically found in sewage or industrial environments.

Maintenance-Free: The material requires minimal maintenance due to its resistance to corrosion, rust, and the buildup of contaminants, which significantly reduces maintenance costs over the long term.

Fire Resistance: SMC materials have a high fire rating, making these covers a safe choice in environments with high fire risk.

Advantages Over Traditional Materials:

| Feature | SMC Composite Covers | Traditional Cast Iron Covers |

|---|---|---|

| Weight | Lighter (30-60% lighter) | Heavier and difficult to handle |

| Corrosion Resistance | Superior, no rust or corrosion | Prone to rust and corrosion over time |

| Maintenance | Minimal, no repainting required | Requires frequent maintenance and painting |

| Load Capacity | Complies with EN124, available in multiple classes | Limited load capacity, prone to cracking |

| Eco-Friendliness | 100% recyclable, eco-friendly | Not recyclable, can contribute to waste |

| Theft Protection | Optional anti-theft locking mechanisms | Susceptible to theft due to high metal value |

Conclusion:

SMC Composite Manhole Covers provide an innovative, long-lasting, and environmentally responsible solution for your infrastructure needs. They combine the best of modern composite materials with engineering precision to offer a reliable, cost-effective, and secure manhole cover solution. Ideal for both high-traffic and industrial environments, they provide a safer, more sustainable alternative to traditional metal or concrete covers.

For custom orders, specific sizes, or more detailed technical information, please contact our sales team for assistance.