Fiberglass Sewer Pipe

Corrosion Resistance

Fiberglass pipes are highly resistant to chemicals, acids, and other harsh materials, ensuring long-term durability without rusting or degrading, reducing the need for frequent repairs.Lightweight and Easy Installation

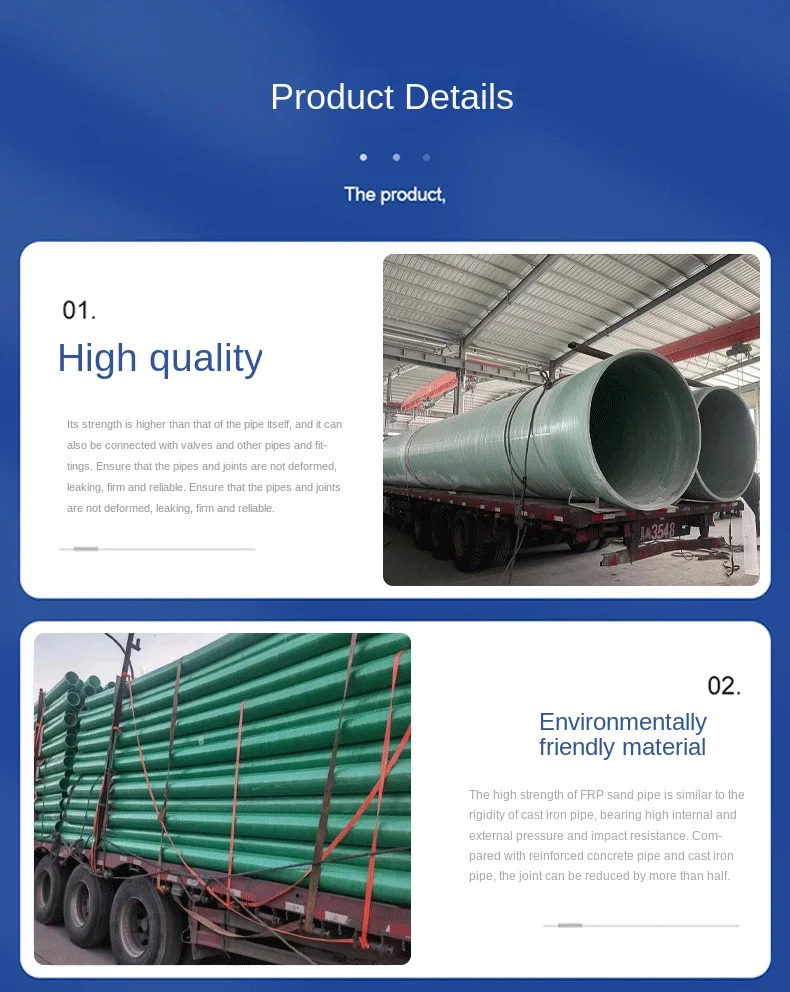

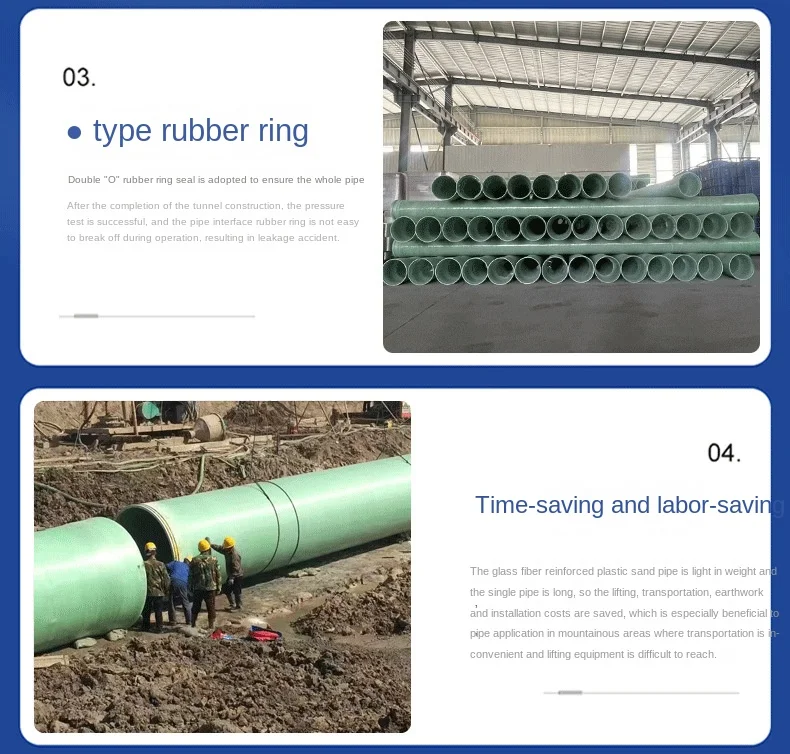

Lighter than steel and concrete, fiberglass pipes are easier to transport and install, cutting down on labor costs and installation time.High Strength and Durability

Despite their light weight, fiberglass pipes are strong and durable, withstanding high internal and external pressures for both low- and high-pressure sewage systems.Smooth Flow and Low Maintenance

The smooth inner surface minimizes friction, improving flow efficiency and reducing blockages. Their corrosion resistance also minimizes maintenance needs, lowering long-term costs.Environmental Benefits

Made from recyclable materials, fiberglass pipes have a lower environmental impact, contributing to sustainability by extending replacement intervals and reducing waste.

Fiberglass Sewer Pipe Product Details

Fiberglass sewer pipes represent a highly reliable, cost-effective solution for modern wastewater and drainage systems. Built from durable, corrosion-resistant materials, these pipes ensure long-term performance in diverse environments, from municipal wastewater to industrial chemical waste management. With advantages like exceptional durability, lightweight construction, and seamless fluid flow, fiberglass pipes are a leading choice for professionals seeking efficiency and low maintenance.

Key Features and Advantages

Superior Corrosion Resistance: Fiberglass is immune to chemical corrosion from acids, bases, and various chemicals often present in sewage, making it ideal for long-term use in demanding wastewater systems.

Lightweight and Cost-Effective Installation: Compared to concrete or metal pipes, fiberglass is significantly lighter, lowering transportation costs and simplifying the installation process with less labor and minimal heavy machinery.

High Structural Strength: Designed to withstand high internal and external pressures, these pipes maintain their integrity under load, providing reliable performance across municipal and industrial sewage applications.

Optimized Flow Efficiency: The smooth inner walls reduce friction, supporting consistent fluid flow that minimizes blockages and reduces the energy costs of wastewater transportation.

Wide Temperature Range: Fiberglass can withstand extreme temperatures, making it resilient against cracking or warping in regions with significant temperature variations.

Environmentally Friendly: Fiberglass pipes are often made with recyclable materials, promoting sustainability. Their durability minimizes the frequency of replacements, supporting a more sustainable approach to infrastructure.

Common Applications

Municipal and Industrial Wastewater Systems

Stormwater and Drainage Management

Chemical Waste Transport

Utility and Infrastructure Projects

Technical Specifications

| Attribute | Description |

|---|---|

| Material Composition | High-strength fiberglass composite materials |

| Available Diameters | Ranging from 100 mm to 2000 mm |

| Length Options | Standard lengths from 6 m to 12 m, with custom lengths available upon request |

| Pressure Rating | Designed to handle up to 16 bar, suitable for both low- and high-pressure systems |

| Temperature Range | Operates efficiently from -40°C to 120°C |

| Corrosion Resistance | Highly resistant to a variety of corrosive agents, including acids, salts, and bases |

| Installation Requirements | Lightweight design for efficient installation, reducing overall project time and cost |

| Certifications | Compliant with ISO 9001, ASTM D3262, AWWA C950 standards for quality and reliability |

| Environmental Impact | Recyclable material, reducing landfill waste and contributing to a more sustainable infrastructure |

Why Choose Fiberglass Sewer Pipes?

Fiberglass sewer pipes provide a high-performance, durable solution for sewage systems that demand corrosion resistance, flow efficiency, and minimal maintenance. As a cost-effective option that is lightweight yet strong, these pipes support modern infrastructure needs by offering long service life, environmental benefits, and flexibility in a wide range of industrial and municipal applications. For projects where durability and ease of maintenance are critical, fiberglass pipes offer an ideal solution that balances performance with sustainability.