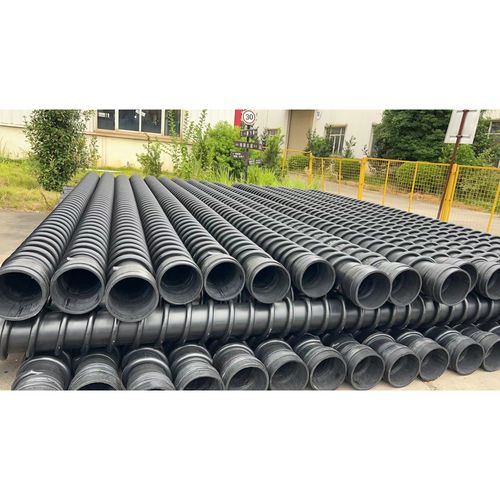

Plastic Sewer Pipe

Corrosion Resistance

Plastic pipes (PVC, HDPE) resist corrosion from chemicals, acids, and salts, extending service life in wastewater and industrial systems.Lightweight and Easy to Install

Plastic pipes are lighter than metal, making them easier and more cost-effective to transport and install in various conditions.Durability and Impact Resistance

With excellent impact resistance, plastic pipes, especially HDPE, are durable in harsh environments and less prone to cracking.Low Maintenance Costs

Their smooth inner surfaces and resistance to corrosion reduce clogging and maintenance needs, saving long-term costs.Environmental Friendliness

Plastic pipes are recyclable, aligning with sustainability goals and reducing environmental impact.

Product Details for Plastic Sewer Pipe

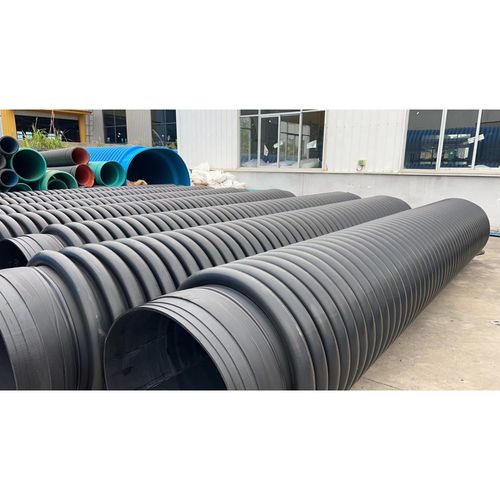

Plastic sewer pipes are a modern solution in sewage and drainage systems, widely used in municipal, industrial, and residential projects. Made from high-quality materials like PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene), these pipes are designed for both performance and longevity. Plastic sewer pipes are highly adaptable to different environmental conditions and are resistant to the wear and tear of chemical exposure, making them ideal for water and wastewater management.

Product Description

Plastic sewer pipes are crafted to deliver consistent performance, ease of installation, and maintenance over time. Their corrosion-resistant and lightweight construction is particularly advantageous for long-term drainage applications. Available in various diameters and pressure ratings, plastic sewer pipes are versatile enough to handle both large-scale municipal sewage systems and residential drainage projects. They are precision-engineered with leak-proof sealing options that enhance reliability and minimize environmental contamination risks.

Key Product Advantages

Exceptional Corrosion Resistance: The materials used (PVC and HDPE) offer excellent protection against chemical reactions and environmental degradation, allowing for durability in corrosive environments.

Lightweight Construction: Significantly lighter than traditional materials, making transport and installation faster, safer, and more cost-effective.

Leak-Resistant Joints: The pipes can be joined with gasketed seals, slip-joints, or solvent welding to ensure secure, leak-proof connections and reduce the risk of sewage leaks.

High Strength and Durability: With a robust design that withstands impacts and external pressures, these pipes are suitable for various load-bearing applications.

Environmentally Friendly: Recyclable and low-impact on the environment due to sustainable manufacturing and materials.

Specifications Table

| Feature | Description |

|---|---|

| Material | High-grade PVC or HDPE, known for strong chemical and corrosion resistance |

| Available Diameters | 100mm, 150mm, 200mm, 300mm, 450mm, 600mm; customizable for specific needs |

| Wall Thickness | Ranges from 3mm to 20mm, adapted to pressure requirements |

| Standard Lengths | 6m and 12m sections; other lengths can be custom-ordered |

| Temperature Range | -40°C to 60°C, suitable for diverse environmental conditions |

| Pressure Rating | PN 6, PN 10, PN 12.5, and PN 16 for moderate to high-pressure systems |

| Joint Types | Slip-joint, solvent-welded, or gasket-sealed for high-efficiency connections |

| Compliance | ISO 9001, ASTM D3035 standards ensuring product quality and reliability |

Applications and Use Cases

Municipal Sewage Systems: Ideal for urban wastewater and stormwater drainage systems where durability and ease of installation are critical.

Industrial Wastewater Management: Resistant to industrial chemicals, making them suitable for factories and industrial zones.

Residential Drainage Solutions: Light and easy to install, perfect for subdivisions, individual residences, and low-rise buildings.

Customization Options

Plastic sewer pipes can be adapted to specific needs with options for different diameters, wall thicknesses, and lengths. Colors and marking options can also be customized to allow easy identification and separation of various drainage lines in complex installations.

Benefits for Installers and Users

Plastic sewer pipes combine cost-effective installation with long-term savings on maintenance. Their lightweight nature allows for reduced labor costs, while leak-proof joints help maintain environmental cleanliness by preventing sewage leaks. Their non-corrosive properties reduce the likelihood of repairs and extend the lifespan, which is beneficial for municipalities and industrial applications alike. The pipes are also 100% recyclable, enhancing their appeal in projects with a focus on sustainability and eco-friendliness.

This combination of resilience, adaptability, and cost-efficiency has established plastic sewer pipes as a preferred choice in modern infrastructure.