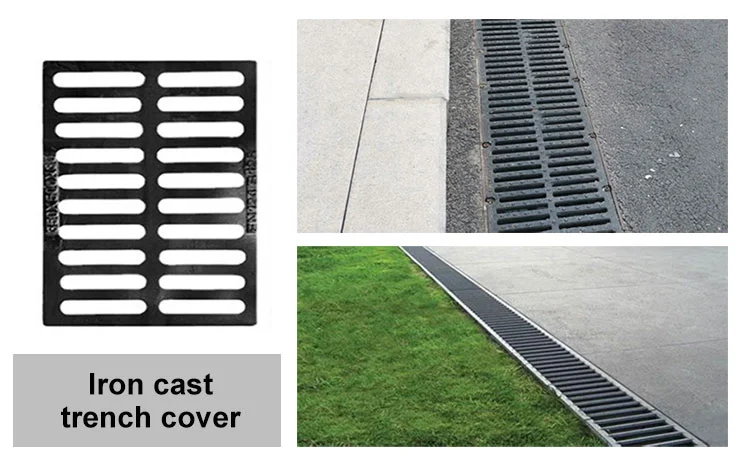

Cast Iron Manhole Cover

Excellent Load-Bearing Capacity

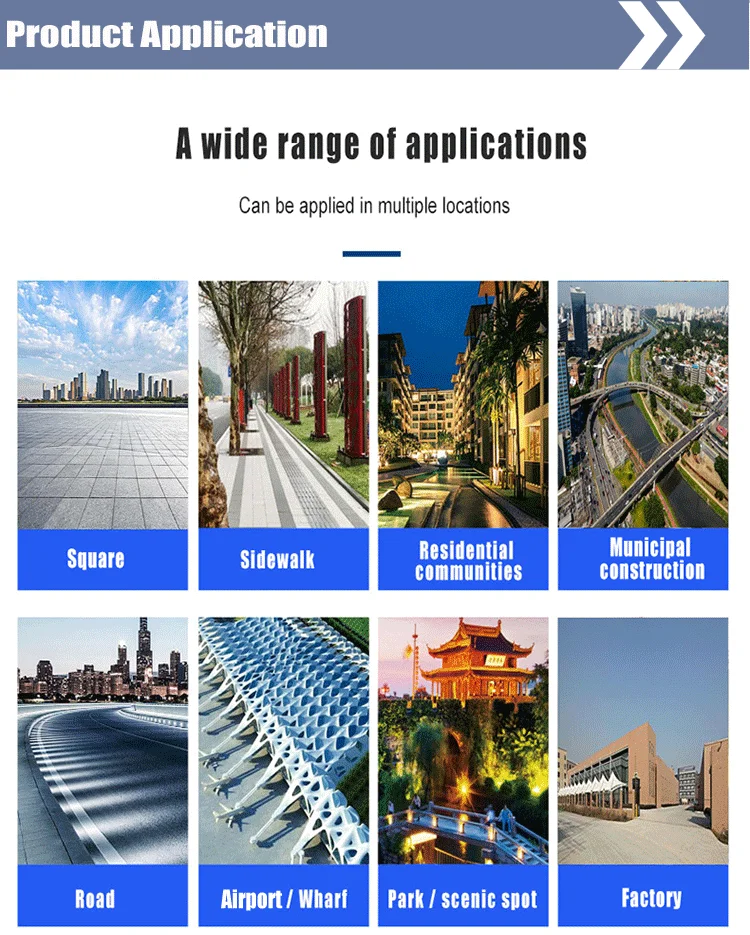

Cast iron manhole covers have a high load-bearing capacity, able to withstand the pressure from heavy traffic and surrounding environments, making them suitable for urban roads, parking lots, and industrial areas, ensuring safe use.Corrosion Resistance

The corrosion resistance of cast iron is strong, allowing it to withstand erosion from water, soil, and other chemicals, extending its service life and reducing maintenance costs.High Wear Resistance

The surface hardness of cast iron manhole covers provides good wear resistance, maintaining integrity and functionality even in high-traffic areas.Safety Features

Designed to be theft-resistant and secure, cast iron manhole covers ensure safety in high-traffic areas. They often come equipped with locking mechanisms to prevent unauthorized access.Environmental Adaptability

Capable of performing in various climatic conditions, including extreme temperatures and humidity, ensuring functionality in different environments.

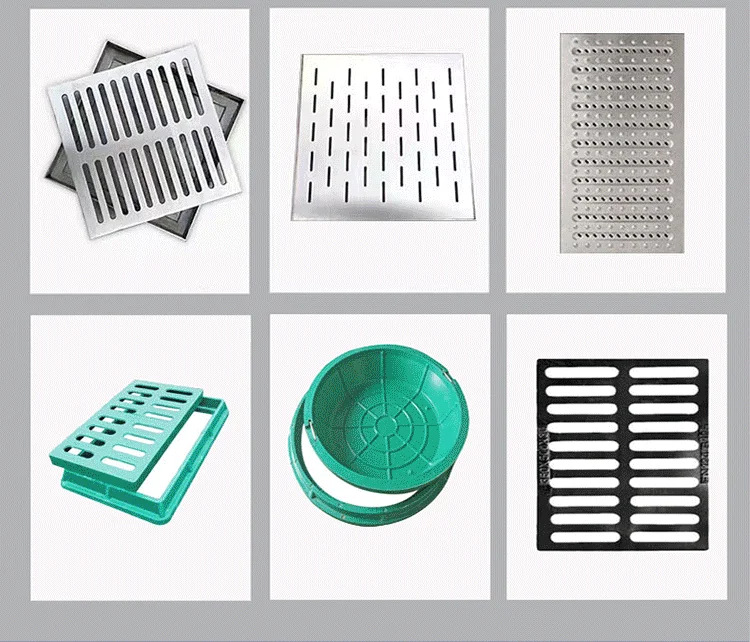

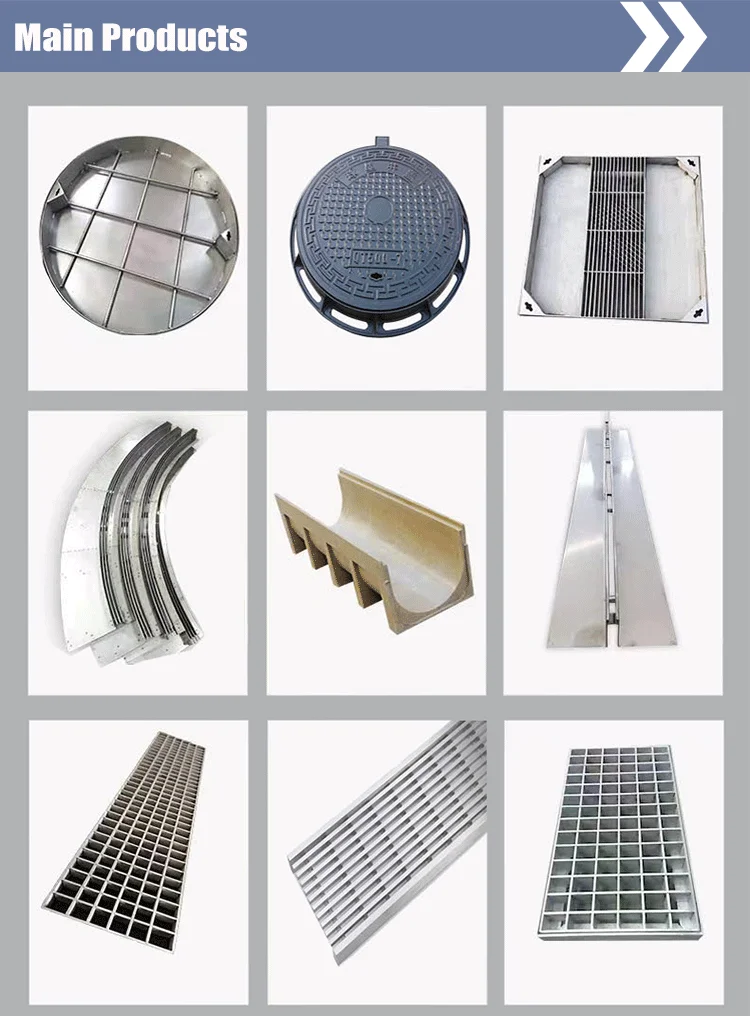

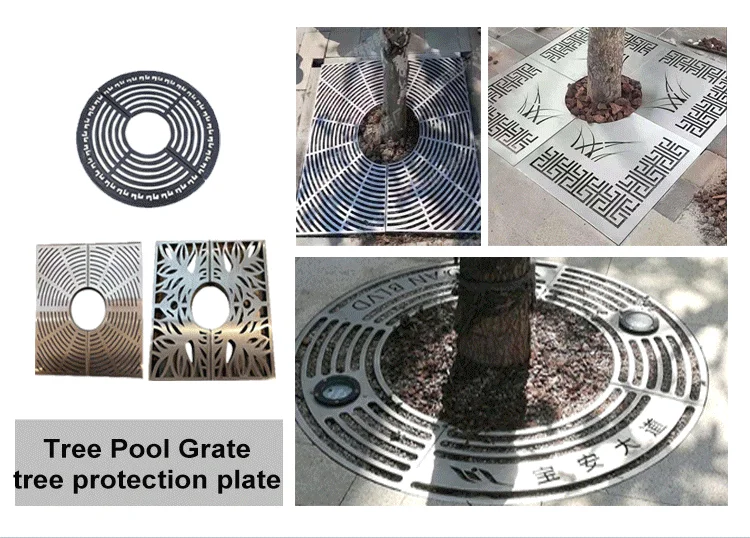

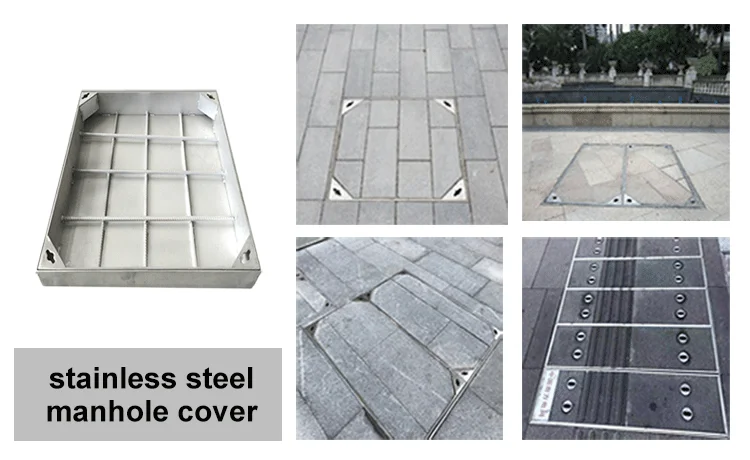

Product descriptions from the supplier

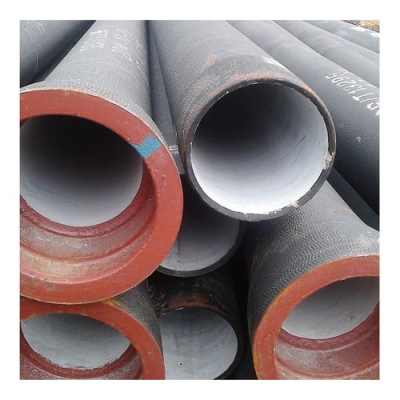

Gray iron HT200-350 (GG20-35, FC200-350);Ductile Iron QT400-QT700(GGG40-GGG70,FCD400-FCD700)

2. Surface treatment: Shot blast, painting; Heat treatment is optional;

3. Custom according to your drawing, specification or samples;