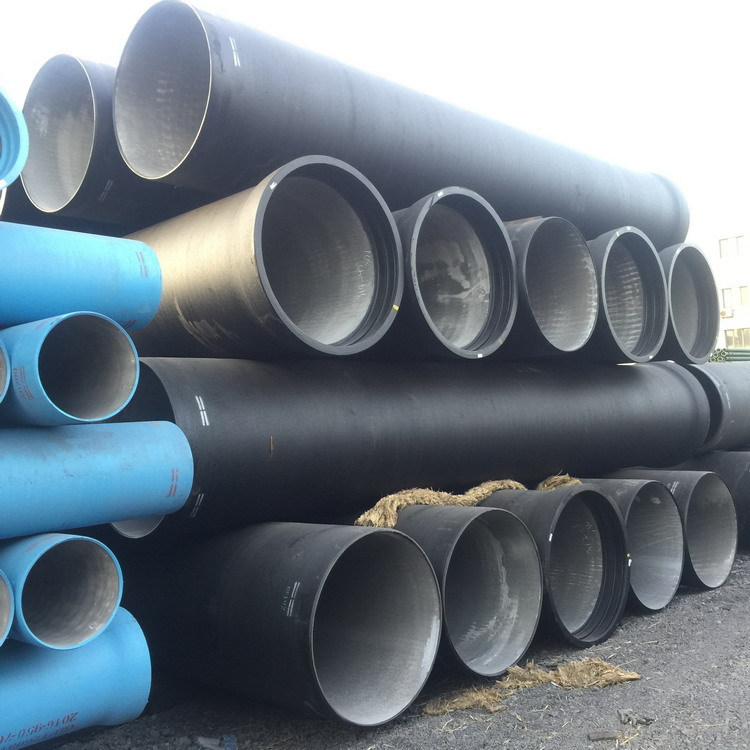

DN 800 Concrete Lined Ductile Iron Pipe

Enhanced Durability

The concrete lining provides an additional protective layer that effectively resists corrosion and wear, significantly extending the lifespan of the pipe. This makes the concrete lined ductile iron pipe particularly suitable for harsh environments, such as wastewater and sewage transportation.High Compressive Strength

Ductile iron itself has excellent compressive properties, and when combined with the strength of concrete, this pipe can withstand heavy loads, making it ideal for busy traffic areas and industrial environments.Outstanding Corrosion Resistance

The concrete lining exhibits strong resistance to chemical substances, especially suitable for transporting fluids that contain corrosive materials. This characteristic reduces maintenance costs and the frequency of replacements caused by corrosion.Good Flow Performance

The smooth surface of the concrete liner minimizes friction resistance as fluids pass through the pipe, optimizing flow efficiency and reducing pumping energy consumption.Environmentally Friendly

This pipe effectively controls the discharge of sewage and wastewater, reducing its environmental impact. Additionally, the recyclability of the materials aligns with sustainable development principles.

Product Details: Concrete Lined Ductile Iron Pipe

Overview

Concrete lined ductile iron pipes are designed to provide robust solutions for various piping applications, especially in environments requiring high resistance to corrosion and mechanical stress. These pipes combine the strength of ductile iron with a smooth concrete lining, offering excellent performance in transporting liquids, including wastewater and industrial fluids.

Key Features

Material Composition: Made from ductile iron, known for its high tensile strength and toughness, coupled with a concrete lining that adds protection against environmental factors.

Diameter Options: Available in various diameters ranging from 4 inches to 48 inches, accommodating a wide range of flow requirements.

Length Specifications: Standard lengths typically range from 10 to 20 feet, facilitating easier installation and handling.

Advantages

Corrosion Resistance: The concrete lining protects the ductile iron core from chemical attacks, making these pipes suitable for wastewater and corrosive applications.

Mechanical Strength: Capable of withstanding heavy loads and high pressures, ensuring reliable performance in both urban and industrial settings.

Improved Flow: The smooth interior surface of the concrete lining reduces friction losses, promoting efficient fluid movement and reducing energy consumption during pumping.

Sustainability: Designed with environmental considerations, these pipes can help reduce pollution and are often recyclable.

Applications

Concrete lined ductile iron pipes are suitable for:

Municipal Water Supply: Reliable transportation of potable water.

Sewage Systems: Effective management of wastewater.

Industrial Applications: Transporting corrosive chemicals and slurries in various industries.

Technical Specifications Table

| Specification | Description |

|---|---|

| Material | Ductile Iron with Concrete Lining |

| Diameter Options | 4" - 48" |

| Length Options | 10' - 20' |

| Pressure Rating | Up to 250 psi |

| Lining Thickness | Typically 1-2 inches |

| Corrosion Resistance | Excellent, suitable for harsh chemicals |

| Weight | Varies by diameter, approx. 100-200 lbs per linear foot |

| Temperature Range | -20°F to 150°F |

Conclusion

Concrete lined ductile iron pipes offer a durable, efficient, and environmentally friendly solution for various piping needs. Their unique combination of strength and resistance to harsh conditions makes them ideal for municipal, industrial, and sewage applications. Investing in these pipes ensures long-term reliability and reduced maintenance costs, contributing to more sustainable infrastructure.